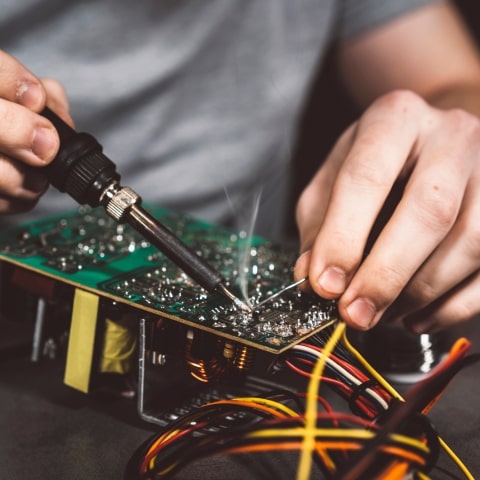

In the intricate world of electronics and metalworking, soldering is a ubiquitous technique used to join components and create reliable connections.

While this process is essential, it comes with an often-overlooked hazard: solder fumes. Solder fumes consist of a complex mixture of gases, vapors, and particulate matter generated during the soldering process.

These seemingly innocuous plumes can pose serious health risks to those exposed to them, making solder fume extraction an imperative concern in any workspace where soldering occurs.

Imagine a scenario where skilled artisans meticulously solder electronic circuits or craft delicate jewelry, each application demanding precision and attention to detail.

Amid this craftsmanship, the release of invisible solder fumes into the surrounding environment becomes a silent threat.

These fumes contain substances like lead, flux, and other harmful compounds that, when inhaled, can lead to a range of health problems, from mild irritation to severe respiratory issues and long-term health complications.

To safeguard the well-being of soldering professionals, solder fume extraction systems have emerged as indispensable tools.

These systems are designed to capture and remove harmful fumes at their source, creating a healthier and safer workspace for soldering enthusiasts and professionals alike.

This introduction explores the critical aspects of solder fume extraction, from its mechanisms and equipment to its vital role in maintaining occupational health and safety.

How does solder fume extraction work

This comprehensive guide will cover everything you need to know about solder fume extraction, from understanding the risks to selecting the right extraction system and maintaining it effectively. For more information visit here.

Understanding Solder Fumes

What Are Solder Fumes?

Solder fumes are the airborne particles and gases produced during the soldering process. These fumes consist of various components, including:

- Vapors: These are the gases created when solder alloys are heated and melted. They can contain harmful substances like lead and other metals depending on the type of solder used.

- Particulate Matter: Tiny solid particles are formed as the solder evaporates. These particles can carry contaminants from the solder and flux.

- Flux Residues: Flux is commonly used in soldering to clean and protect surfaces. When heated, it can release volatile organic compounds (VOCs) and become part of the solder fumes.

Health Risks Associated with Solder Fumes

Inhaling solder fumes can lead to a range of health problems, including:

- Respiratory Irritation: Fumes can irritate the nose, throat, and lungs, leading to symptoms like coughing, sneezing, and shortness of breath.

- Acute Health Effects: Short-term exposure to high concentrations of solder fumes can cause symptoms such as headaches, dizziness, nausea, and eye irritation.

- Chronic Health Effects: Long-term exposure to low levels of solder fumes can lead to more severe health issues, including lung damage, neurological problems, and reproductive issues.

- Lead Poisoning: Solder often contains lead, which can accumulate in the body over time and lead to lead poisoning. Symptoms may include fatigue, joint pain, and cognitive impairment.

Legal and Regulatory Compliance

Many countries have regulations and guidelines in place to protect workers from exposure to hazardous substances, including solder fumes.

Employers are generally required to provide a safe working environment and implement measures to control solder fume exposure. Familiarize yourself with your local occupational health and safety regulations to ensure compliance.

Solder Fume Extraction Systems

How Solder Fume Extractors Work

Solder fume extractors are designed to capture and remove harmful fumes at their source, creating a safer working environment. They typically consist of the following key components:

- Hood or Capture Device: This is placed near the soldering area to capture the fumes as they are generated.

- Ducting: A system of ducts or hoses transports the captured fumes to the extraction unit.

- Extraction Unit: This unit contains the fan, filters, and other components necessary to remove contaminants from the air.

- Filtration System: Filters (e.g., HEPA and activated carbon) in the extraction unit remove particulates and harmful gases from the air.

- Exhaust System: Cleaned air is exhausted back into the workspace or safely vented outside.

Types of Solder Fume Extractors

There are several types of solder fume extraction to choose from:

- Benchtop Extractors: Compact and portable units designed for small-scale soldering operations.

- Ductless Fume Hoods: Ideal for laboratories and situations where ducting isn’t feasible. They use filters to clean the air and recirculate it back into the room.

- Ducted Fume Extractors: Larger systems that are connected to an external exhaust system. They are suitable for larger production environments.

- Mobile Extractors: Mounted on wheels for easy mobility, making them adaptable to changing workspaces.

Selecting the Right Extractor for Your Needs

When choosing a solder fume extraction, consider the following factors:

- Soldering Scale: The size and frequency of your soldering operations will influence the type and size of extractor you need.

- Location: Determine whether you have the option to vent fumes outside or if you require a ductless system.

- Filtration Requirements: Consider the types of fumes and particulates you’ll be dealing with to select appropriate filters.

- Budget: There are options available for various budgets, so it’s essential to balance cost with safety.

Components of a Solder Fume Extraction System

Extraction Unit

The solder fume extraction unit is the heart of the fume extraction system and typically includes:

- Fan: Creates airflow to draw fumes into the system.

- Filters: Removes contaminants from the air. Common filter types include HEPA filters (for particulates) and activated carbon filters (for gases).

- Control Panel: Allows you to adjust fan speed and monitor filter status.

Ducting and Hoods

- Hoods or Capture Devices: Positioned near the soldering area to capture fumes. Proper hood placement is crucial for effective extraction.

- Ducts or Hoses: Transport captured fumes from the hood to the extraction unit. Ensure that ducting is appropriately sized and free from obstructions.

Filtration System

The filtration system’s primary role is to purify the air by removing harmful substances. Common types of filters include:

- HEPA Filters: Highly efficient at trapping particulate matter, including fine soldering fumes.

- Activated Carbon Filters: Effective at adsorbing and neutralizing gases and VOCs.

- Pre-filters: Extend the lifespan of primary filters by capturing larger particles.

Exhaust System

The exhaust system directs clean air either back into the workspace or outside the building, depending on the setup. It should meet local regulations and provide a safe solution for fume disposal.

Installation and Setup

Proper Placement of Extractors

The correct placement of solder fume extraction is crucial for effective extraction. Consider the following tips:

- Position the hood close to the soldering work: Ensure that the hood captures fumes as close to the source as possible.

- Adjust the hood angle: Angle the hood to capture rising fumes effectively.

- Avoid obstructions: Ensure that there are no obstacles blocking the airflow path from the hood to the extraction unit.

Ducting Configuration

For ducted systems, plan the ducting configuration carefully:

- Straight and Short Ducting: Minimize bends and keep ducting as short as possible to maintain airflow efficiency.

- Use Smooth Ducts: Smooth-walled ducts reduce air resistance and improve performance.

Electrical Requirements

Ensure that the electrical supply for your fume extractor meets the system’s requirements. Use a qualified electrician to set up power connections safely.

Maintenance and Filter Replacement

Proper maintenance is essential to keep your solder fume extraction system operating efficiently and effectively.

Regular Maintenance Tasks

- Visual Inspection: Regularly check for visible damage or wear on all components, including hoses, filters, and fans.

- Filter Replacement: Follow the manufacturer’s recommendations for filter replacement schedules. This typically ranges from several months to a year, depending on usage.

- Cleaning: Periodically clean hoods and ducts to prevent obstructions that can reduce extraction efficiency.

Filter Replacement Schedule

HEPA and activated carbon filters have a finite lifespan and must be replaced as they become saturated. Keep a schedule and track filter usage to ensure timely replacement.

Cleaning and Care

- Hood Cleaning: Wipe down hoods regularly to remove solder residue and dust.

- Duct Cleaning: Inspect and clean ducts if necessary to maintain proper airflow.

Safety Considerations

Personal Protective Equipment (PPE)

While solder fume extraction is essential, it should not replace the use of appropriate personal protective equipment (PPE). Depending on the soldering process and materials used, PPE may include:

- Safety Glasses: Protect your eyes from splashes and airborne particles.

- Respirators: Use respirators with appropriate filters to protect against fumes and particulates.

- Gloves: Wear gloves to protect your hands from hot solder and materials.

Fire Safety

Soldering involves heat, which can pose a fire hazard. Follow these fire safety tips:

- Fire Extinguishers: Keep fire extinguishers readily accessible and ensure that personnel know how to use them.

- Flame-Resistant Surfaces: Work on non-combustible surfaces and avoid placing flammable materials near soldering stations.

Electrical Safety

- Grounding: Ensure that all electrical equipment, including soldering irons, is properly grounded to prevent electrical shocks.

- Cord Management: Keep cords and cables organized to prevent tripping hazards and damage.

Eco-Friendly and Sustainable Options

Consider eco-friendly practices when implementing solder fume extraction:

Energy Efficiency

Choose energy-efficient extraction units and run them only when necessary to reduce energy consumption.

Recycling and Disposal of Filters

Properly dispose of used filters and consider recycling options when applicable, especially for materials like activated carbon.

Conclusion

In conclusion, solder fume extraction is a critical aspect of maintaining a safe and healthy work environment when soldering.

Understanding the risks associated with solder fume extraction, selecting the right extraction system, and adhering to safety practices will help ensure your well-being and the effectiveness of your soldering operations.

Regular maintenance and responsible disposal of filters contribute to both safety and environmental sustainability.

Always prioritize safety and compliance with local regulations when working with soldering equipment.