Welding Fume Extractor

The original welding fume exhaust arm is the perfect solution for welding fume extractor in workshop. Our products ensure the best smoke and dust capture capability and maneuverability. The extractor is suspended from a rotating device that allows the product to rotate 360 degrees. This makes the extraction arm flexible in all directions and very simple to locate. The original extraction arm can be installed on the exhaust rail or fixed or portable filtration equipment in combination with different brackets and extension arms. Can be mounted on ceiling, wall, workbench or extension support. A wide range of accessories offers unlimited possibilities to match the needs of any workplace.

Technical data | Welding fume extractor |

|---|---|

| Airflow (CFM) | 30cfm-290cfm |

| Certifications | CE |

| Extraction arm diameter (in) | 3in-3.6in-4in |

| Fume temperature | Max 85 C |

| Installation | Indoor installations |

| Material | The joints and pipes are made of PP plastic. TPE anti-slip joint damping seal. Polypropylene plastics |

| Noise level (dB) | 58dB- 62dB |

It is the perfect solution for welding fume exhaust in workshop. It ensure the best smoke and dust capture capability and maneuverability. The extractor is suspended from a rotating device that allows the product to rotate 360 degrees. This makes the extraction arm flexible in all directions and very simple to locate. The solder fume extractor can be installed on the exhaust rail or fixed or portable filtration equipment in combination with different brackets and extension arms. Can be mounted on ceiling, wall, workbench or extension support. A wide range of accessories offers unlimited possibilities to match the needs of any workplace.

It adopts filtering technology, which provides a solution to deal with welding fume. It is specially designed to capture welding fume. The mobile fume purifier provides services for customers who need to purify fume. Before the welding fume enters the welder’s breathing belt, the fume purifier can capture it at the dust producing point. The filter element further traps these harmful submicron particles on the surface of the nanofiber membrane to prevent them from being circularly blown into the plant air. It is widely used and has made great contributions to the protection of earth greening.

It is applied to the purification of fume and dust generated in various welding (electric arc welding, carbon dioxide shielded welding, MAG welding, carbon arc gouging welding, gas fusion cutting, special welding, etc.) polishing, cutting, grinding and other places, as well as the recovery of rare metals and precious materials. Double arm powerful power welding fume purifier

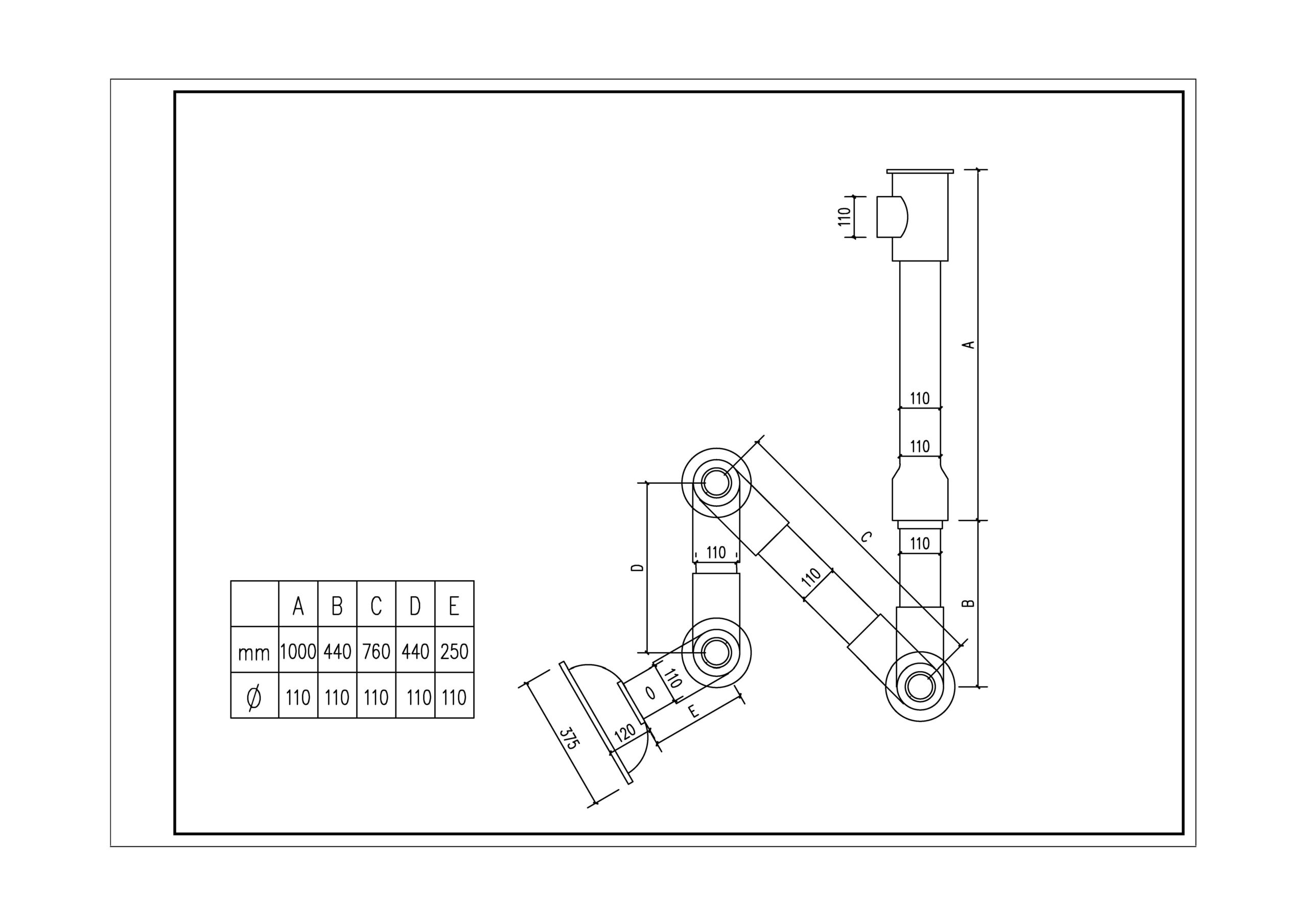

Ash cleaning method, manual cleaning, compressed air back blowing cleaning, arm length (m): 2m or 3m

Product features

1. The shell of the purifier is sprayed with plastic, which is beautiful and elegant. Four universal rubber wheels are installed at the bottom, which can be moved in the workplace

2 Fan design, large air volume, low power consumption.

3 The suction hood can be extended to any desired position along with the suction arm. It can be equipped with flexible suction arms or two flexible suction arms. The suction arm can move 360 ° at will, and smoke can be removed from the place where the smoke occurs, greatly improving the collection rate of smoke.

4. The filter cartridge is made of laminated polyester fiber, which has higher adsorption performance, better safety, filtering effect>99.9%, long service life and can absorb 0.3 μ M dust particles.

5. Blowback device: remove the dust after manually removing the filter cartridge or connect the air compressor for semi-automatic dust removal.

6 Clean air shall be uniformly guided and dispersed from the direction of grid type air outlet, and sound insulation cotton shall be built in the casing to minimize the noise.

Matters needing attention

1. It is strictly prohibited to absorb dust with explosive, flammable, viscous and strong chemical composition. Please consult relevant technicians for ordering time.

2. The dust remover can be designed and customized according to the customer’s on-site working conditions.